No products found

Menu

Choosing the right marking machine is an important decision you should make with your eyes towards achieving quality and efficiency. There are many types of marking machines, and several factors play a huge role in your decision. At Baokun laser, our belief is centered on quality, whether while marking your products or selling our products. Therefore, on careful analysis of each marking process of relevance today and the features required for successful marking, we have three marking machines you should consider.

| Laser type | Laser wavelength | Average output power |

| Fiber Laser | 1064nm | 30-100W |

| Optical isolator | Modulation frequency range | Linear speed |

| Yes | 20KHz- 80KHz | 70000 mm/s |

| Repeat positioning accuracy | Marking range | Laser source |

| 0.003mm | 100*100mm – 300*300mm | Raycus |

This model is a 10mm standard product, which has advantages of high precision, high speed, and high stability and mainly applies to laser marking, flying marking, and 3D printing.

We continue to provide a wide variety of high-quality and reliable production equipment with accompanying engineering support services for laser engraving cutting machines.

Industrial computer adopted which is equipped 8GB RAM SSD WIN10 system 19″ LCD for running our laser machine more smoothly.

Laser safety signs are used in areas that need to control the laser and can guide relevant personnel to instruct the safe use of the laser system.

Medical level, built-in active PFC. Medical safety approved (MOOP level). High efficiency, no-load power consumption less than 0.5W-0.8W.

The laser emission indicator provides a visible signal during the emission of accessible laser radiation in excess of the accessible emission limits of Class I.

Safety interlocks are designed to prevent customers’ access to laser and collateral radiation upon removal or displacement of such portion of the protective housing.

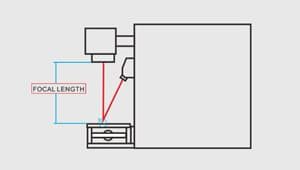

Convenient to adjust the focal length, preview the working area, graphic size, graphic outline, and visual marking path.

| Laser Power | 20W | 30W | 50W | 100W | ||

| Working Area | 70X70mm / 110X110mm / 150X150mm | |||||

| laser Wavelength | 1064nm | |||||

| Frequency | 1KHz~400KHz | |||||

| Graphic Format Supported | bmp, jpg, gif, tga, png, tif, ai, dxf, dst, plt, etc. | |||||

| Laser Module Life | >100,000 hours | |||||

| Power Supply | 220V±10% 50HZ or 110V±10% 60HZ | |||||

| Marking Depth | adjustable according to materials | |||||

| Scanning Speed | 0~7000mm/s | |||||

The laser marking machine can provide the best marking effect. Especially good at marking the smallest characters.

The precision of the metal laser marking machine can reach 0.001mm, while the diode is only 0.01mm.

The fiber laser marking machine has a lifespan of 100,000 hours and can be used for more than 30 years.

The metal laser marking machine can be used for metal marking for 8-10 years without any consumables.

Built-in fiber laser head, almost maintenance-free and absolutely reliable. Laser markers use very low energy consumption and incur no consumables, spare parts, or laser maintenance costs.

Fiber laser marking machines have been developed to mark a large number of small and medium parts. Laser marking machines are capable of marking pens, USB sticks, or nameplates in seconds.

The pre-installed fiber laser marker software is like a printer driver, it works with all graphics, CAD, and label printing software, no need to import or convert, just use a simple print command.

The fiber laser marking machine adopts a fully enclosed design and can work continuously and normally in a variety of environments.

The upper and lower double exchange worktable design can be selected, the inverter is responsible for controlling the exchanging motor, and the machine can complete the worktable exchange within 13s at the fastest.

The laser marking area has four options: 70mmx70mm, 110mmx110mm, 150mmx150mm, and 300mmx300mm, and you can choose different scanning lenses for different laser marking work areas.

Laser protective glasses are used to reduce the intensity of potentially harmful lasers to the safe range. They can provide exponential attenuation of optical density for different laser wavelengths, and at the same time allow enough visible light to pass through for easy observation and use.

When the laser marks different materials, it will produce a lot of smoke, dust, and pungent stench. The smoke purification system can carry out an instant purification system of severe pollutants. The purified clean air can be directly discharged into the room without passing through an external discharge pipe.

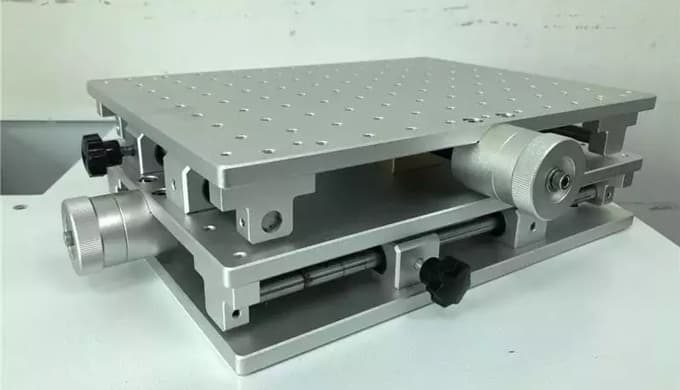

Glorious Laser offers a variety of pre-assembled X/Y adjustable tables to meet customer requirements for indexing, scanning, fixing, positioning and measuring. These tables are designed based on our many years of experience in the laser industry and are available in manual and motorized configurations.

The fiber laser metal marking machine is suitable for marking stainless steel, mild steel, carbon steel, alloy steel, spring steel, iron, galvanized iron, galvanized, aluminum, copper, brass, and other metal.

There are four types of laser marking machines that you can consider for marking a product. Each one has its features and material compatibility, making knowing them very important before selecting one.

Fiber laser markers have a wide compatible material, mainly metals, plastics, and glasses. They are efficient, reliable, cost-effective, and deliver quality and permanent markings. Fiber laser marking machines are compatible with the types of laser marking systems discussed above. However, unlike other machines, it is the only machine suitable for laser etching because of the wavelength at which it operates.

The UV laser markers are suitable for marking plastics, metals, and glasses. The machine uses UV light which marks by breaking the bond between atoms holding the material surface together.

UV laser marking machines do not cause peripheral heating, unlike fiber laser markers and CO2 laser markers. Therefore, it does not pose any risk to the material integrity after use. Nevertheless, UV laser marking machines are effective and efficient.

Green laser markers are the ideal machine for marking products that are heat sensitive. This is because they operate at a wavelength of 532nm, i.e., it is a low-powered machine with a lesser tendency of burning materials such as soft plastics.

CO2 laser markers are a very powerful type of laser marker that uses a CO2 gas mixture. They are the suitable laser marker for marking any non-metallic material such as acrylic, PVC, rubber, leather, etc. Consequently, they are a huge part of the printing and packaging industry, advertising industry, model industry, etc.

Laser markers have wide use in different industries in marking different designs, based on their compatibility with different materials. It is suitable for marking both no-metal and metal materials, including stainless steel, aluminum, silver, gold, etc.

At baokun, we regard every request from our customers as first priority. Our team is always ready to give technical support for any customer at any time. All of our machines boast a warranty period of 3 years and lifetime of free technical consultation.

QINGDAO PRECISION LASER TECHNOLGY CO.,LTD produced a series of fiber laser cutting machine with high electro-optic conversion efficiency, A number of technologies, especially metal fiber laser cutting technology in terms of cutting thickness and cutting speed are advanced in China.