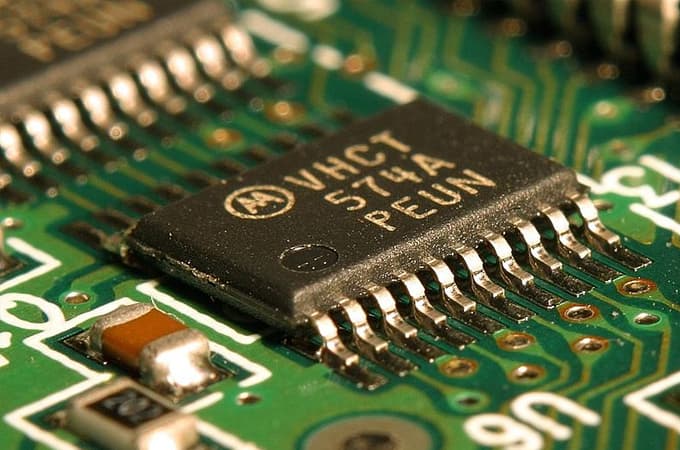

The chip is characterized by small size and high integration density. The precision requirements in the process of processing and marking the chip surface are very high. It is required to mark clear text, model, manufacturer, and other information without damaging the components. For process standards, this requires the laser marking machine to be more precise, which puts more demands on laser marking. Combining the chip marking requirements and referring to the laser marking process, is only the most ideal choice. Then laser marking machine is a good choice.

The laser marking machine has a thin spot, which can engrave durable logos. The characteristics of the logo are exquisite and beautiful, and will not damage the functional properties of the chip. The structure design of the IC automatic laser marking machine is modular and can be reorganized. , Can realize mass production quickly, is compatible with a variety of products of different specifications.

The fiber laser marking machine has high electro-optical conversion efficiency and adopts an air-cooled cooling method, the whole machine is small and exquisite, the output beam quality is good, and the reliability is high. It can engrave metal materials and some non-metal materials. It is mainly used in fields that require high depth, smoothness, and fineness, such as clocks, jewelry, mold industries, IC chips, bitmap marking, etc. Nowadays, integrated IC has a great effect on electronic, electrical, and daily life. This has also created a greater development trend for the development trend of integrated IC fiber line laser engraving machine technology.

It is necessary to mark permanent characters of about 0.5mm in size and corporate logo patterns on the surface of the IC chip packaging glue for product identification and tracking and corporate publicity. Due to the small IC area and high marking position accuracy (less than 0.05mm), laser marking is suitable. At the same time, combined with the design of the electromechanical system can realize the flexible production of multi-variety, small batch IC marking.

The laser’s UV laser marking machine adopts a high-performance UV laser and digital high-speed scanning galvanometer to make up for the shortcomings of infrared laser processing; small heat-affected area, good beam quality, and small focus spot can realize ultra-fine chip laser marking; Suitable