Menu

| Laser power | Max. linkage speed | Max. Acceleration | ||

| 1kw-6kw | 140m/min | 1.5G | ||

| Positioning accuracy | Repositioning accuracy | Laser source | ||

| 0.05mm | 0.03mm | MAX / IPG Raycus / GW | ||

| Laser head | System identification file format | Working area | ||

| WSX / Raytools / hans | G file、DXF、PLT、AI | Customizable |

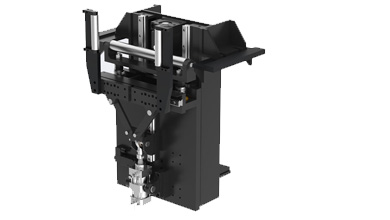

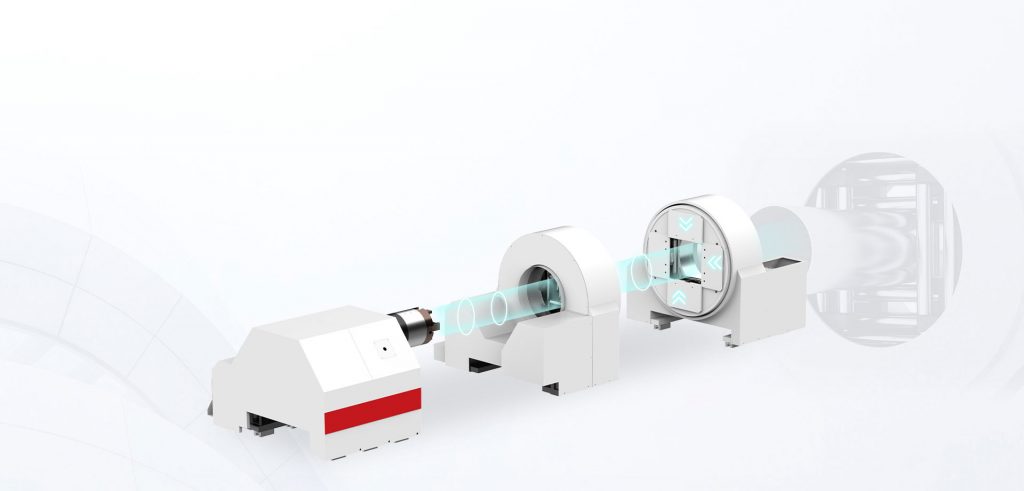

Independent research and development, square hole design, strong passing ability.

Both ends are punched, intersecting lines are cut, and the clamping force is twice that of ordinary chucks.

Strong support, automatic correction, two chucks to avoid shaking.

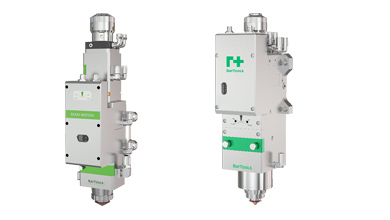

The focal length can be adjusted automatically, no manual operation is required, the cutting precision is high, and the built-in double water cooling structure is adopted.

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

It is suitable for big or small pipe, self-centering for various pipes, strong support and load-bearing, a single support material for pipe loading can reach 120Kg; a single support for heavy pipe loading can reach 330Kg.

1. Low noise and long life 2. Efficient and energy saving 3. Wide range of uses 4. Tamagawa encoder 5. High Presicion

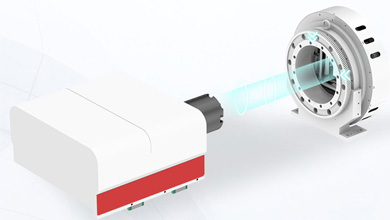

offer the best value, most stability and the highest productivity. They are built to last with their solid state monolithic design with 20x less degradation than competitors.

| Model | 1000w-6000w | |||||

| Tube size range | Round tube: Φ20-Φ220mm; Square tube: 20-150mm | |||||

| Maximum machinable tube length | 6500mm | 9200mm | ||||

| Maximum tube weight | 100Kg; 16.6Kg/m | 200Kg; 21.7Kg/m | ||||

| Maximum blanking length | 4500mm | |||||

| Shortest remaining material | 20mm | |||||

| Dimensions | 7500mm x 6500mm x 2500mm | |||||

| Machine weight | 6000kg | |||||

| Positioning accuracy | 0.05mm | |||||

| Repositioning accuracy | 0.03mm | |||||

| X axis maximum speed | 100m/min | |||||

| Y axis maximum speed | 95m/min | |||||

| Y axis maximum speed | 1G | |||||

| Y maximum acceleration | 1G | |||||

| Auxiliary feeding tube types | / | Round tube, square tube, rectangular tube | / | / | Round tube, square tube, rectangular tube | / |

| Auxiliary feeding tube size range | / | Round tube: Φ20-Φ220mm; Square tube: 20-150mm | / | / | Round tube: Φ20-Φ220mm; Square tube: 20-150mm | / |

| Auxiliary feeding maximum machinable tube length | / | 6500mm | / | / | 9200mm | / |

| Auxiliary feeding maximum load capacity of storage bin | / | 1.5T | / | / | 1.5T | / |

| Auxiliary feeding location number | / | 6 | / | / | 6 | / |

It provides real-time pressure detection, pushes abnormal information when the pressure value is lower than the best cutting effect and accuracy, to ensure the cutting effect, cutting accuracy, and the timeliness of gas replacement.

The automatic lubrication system provides regular and quantitative lubricating oil for the equipment to ensure the normal high-speed operation of the equipment and has functions such as abnormal alarm and liquid level alarm. The system greatly improves the cutting efficiency and effectively prolongs the service life of the transmission mechanism.

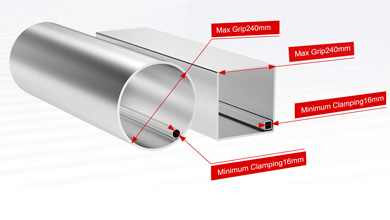

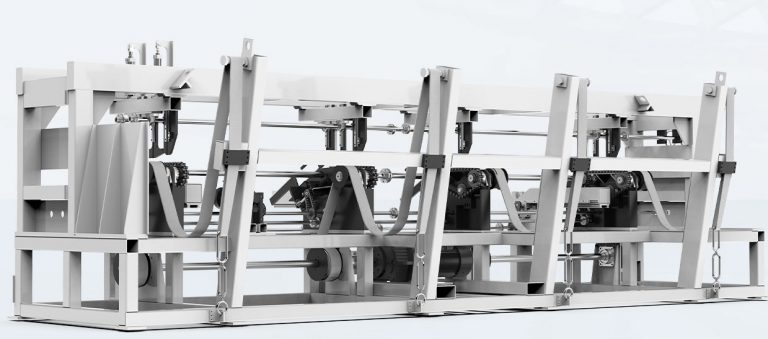

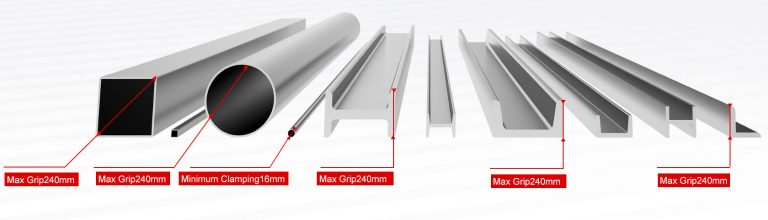

The maximum processing pipe weight is 1000kg, the diameter range of round or square pipe is 16-240mm.

Pipe length is 6200mm, angle steel, channel steel, I-beam and other profiles are all supported.

It is seamless connected with cutting machine, precisely loading, fast loading speed, only 15s for per tube; strong load-bearing capacity, the maximum load of the whole machine can reach 5 tons.

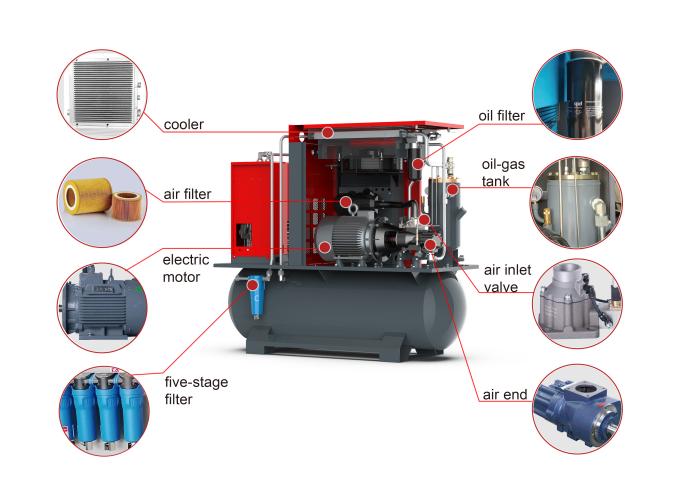

Control: PLC,Driven: direct,Cooling: by air

Electric motor: Permanent magnet variable speed type, 20hp 15KW 380v/50hz/3ph IP65 oil cooling type.

Invertor: Inovance

Discharge temperature: less than ambient +8 ℃

Noise: less than 65 dB(A),Air outlet size: G3/4”

Air tank: 500L,Air dryer capacity: 2.35 m3/min

Air filter: 3 pcs(after filtering, particle content 0.01 micron, oil content 0.001mg/m3)

The three chucks can realize mutual shift and fine cutting. The self-developed full-stroke chuck can realize the cutting and feeding of pipes of any length, and use the entire pipe as much as possible to achieve “zero tail material” cutting.

The maximum processing pipe weight is 1000kg, the diameter range of round or square pipe is 16-355mm.

Pipe length is 9300mm, angle steel, channel steel, I-beam and other profiles are all supported

| Material | Cutting Limit | Clean Cut |

| Carbon Steel | 12mm | 10mm |

| Stainless steel | 6mm | 5mm |

| Aluminum | 4mm | 3mm |

| Brass | 3mm | 2mm |

| Copper | 3mm | 2mm |

| Galvanized steel | 3mm | 2mm |

The CNC laser cutting machine can cut all types of metals, from mild steel to stainless steel as well as non-ferrous metals. But some highly reflective metals, such as aluminum and copper, are more difficult to cut. The maximum thickness of the metal that the laser can cut is determined by the laser source. In theory, the greater the laser power, the greater the thickness that can be cut. In addition, the professional knowledge of the machine operator will also affect the thickness of the laser cutting.

Processing Range

The maximum processing pipe weight is 1000kg, the diameter range of round or square pipe is 16-355mm.

Pipe length is 9300mm, angle steel, channel steel, I-beam and other profiles are all supported

Fiber laser cutting machines are widely used in the manufacturing of advertising signs, kitchenware, sheet metal processing, metal parts, chassis and rack processing, cabinet processing, metal crafts, elevator panel cutting, hardware, auto parts, and electronic parts, nameplates, etc

At baokun, we regard every request from our customers as first priority. Our team is always ready to give technical support for any customer at any time. All of our machines boast a warranty period of 3 years and lifetime of free technical consultation.

QINGDAO PRECISION LASER TECHNOLGY CO.,LTD produced a series of fiber laser cutting machine with high electro-optic conversion efficiency, A number of technologies, especially metal fiber laser cutting technology in terms of cutting thickness and cutting speed are advanced in China.