No products found

Menu

| Laser power | Max. linkage speed | Max. Acceleration |

| 1kw-6kw | 140m/min | 1.5G |

| Positioning accuracy | Repositioning accuracy | Laser source |

| 0.05mm | 0.03mm | MAX / IPG Raycus / GW |

| Laser head | System identification file format | Working area |

| WSX / Raytools / hans | G file、DXF、PLT、AI | Customizable |

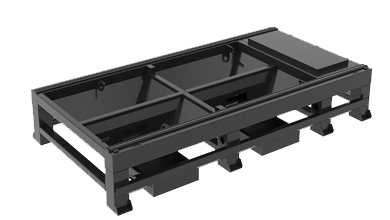

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by multi-end rectangular tubes. The inside of the tube is provided with reinforcing ribs to increase the strength and tensile strength of the bed. In addition, we apply stress annealing technology to strengthen the strength and tensile strength of the bed, and effectively avoid the deformation of the bed.

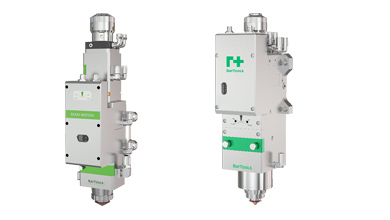

The focal length can be adjusted automatically, no manual operation is required, the cutting precision is high, and the built-in double water cooling structure is adopted.

Micro-connection cutting

Active obstacle avoidance

Real-time monitoring of core components

Active reminder of machine maintenance

The beam is artificially aged, solution treated, and finished, and has good integrity, stiffness, surface quality, toughness, and ductility. The beam is die-cast with steel mold, which is stable, durable, and efficient.

offer the best value, most stability and the highest productivity. They are built to last with their solid state monolithic design with 20x less degradation than competitors.

1. Low noise and long life 2. Efficient and energy saving 3. Wide range of uses 4. Tamagawa encoder 5. High Presicion

| Model | BKJ-F-3015T | BKJ-F-4020T | BKJ-F-6020T | BKJ-F-6025T | BKJ-F-8025T |

| Working area(mm) | 3000*1500 | 4000*2000 | 6100*2000 | 6100*2500 | 8100*2500 |

| Power | 1KW-6KW | ||||

| Table load bearing | 900kg | 1600kg | 2400kg | 2950kg | 6000kg |

| Machine overall dimension | 9350*2300*2000 | 10200*3100*2000 | 15100*3100*2000 | 15300*3600*2200 | 19200*3600*2200 |

| Machine weight | 3600kg | 5600kg | 7500kg | 8500kg | 9000kg |

| Position gaccuracy | 0.03mm | 0.05mm | |||

| Repositioning accuracy | 0.02mm | 0.03mm | |||

It provides real-time pressure detection, pushes abnormal information when the pressure value is lower than the best cutting effect and accuracy, to ensure the cutting effect, cutting accuracy, and the timeliness of gas replacement.

The automatic lubrication system provides regular and quantitative lubricating oil for the equipment to ensure the normal high-speed operation of the equipment and has functions such as abnormal alarm and liquid level alarm. The system greatly improves the cutting efficiency and effectively prolongs the service life of the transmission mechanism.

The laser head keeps a distance from the workpiece during the cutting process to reduce the risk of collision and will stop cutting when it may collide with the board. The safety follows module reduces the accident rate.

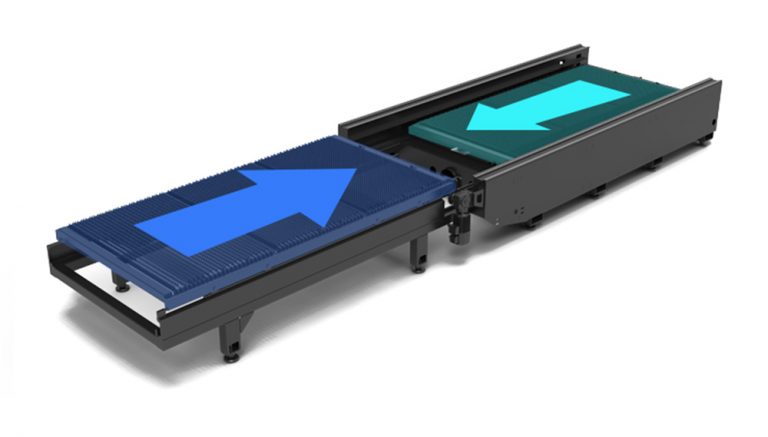

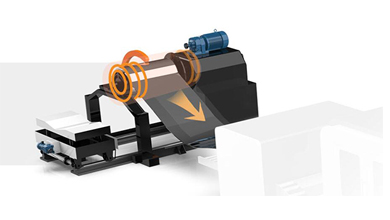

The BKJ-F-3015 series adopts a motor gear transmission system, which can complete the exchange within 12 seconds at the fastest. The BKJ-F-4020 and above series adopt chain transmission. The fast pallet changer greatly improves laser cutting machine work efficiency.

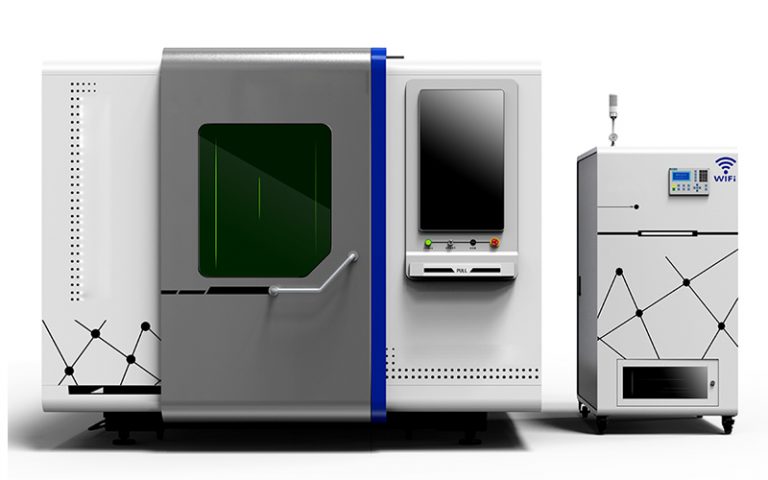

It can be equipped with a fully enclosed laser protective cover (with a special laser protective glass observation window), and a fume recovery and purification system to reduce light pollution and smoke pollution caused by laser cutting during equipment operation. And we are equipped with high-definition monitoring equipment to achieve 360° monitoring in the cutting state to prevent misoperation

The laser cutting loading and unloading system can automatically pick up various sheets cut on the laser worktable. Small workpieces will be placed in a container and will place larger workpieces on a pallet or transport truck for sorting. And a large number of workpieces can be sorted through various controllable vacuum suction cups.

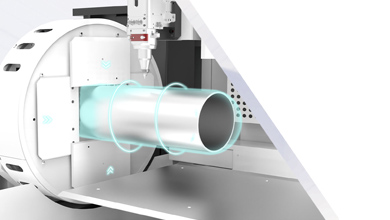

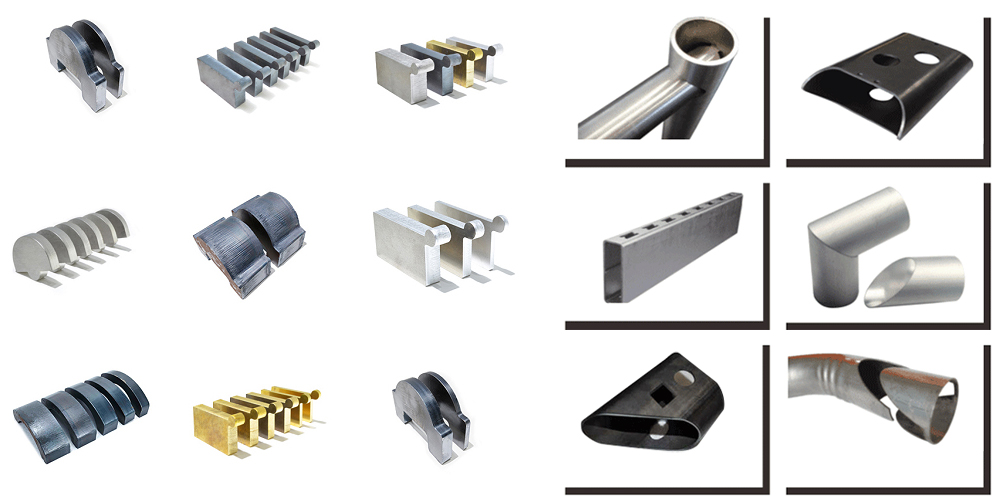

The CNC laser cutting machine can cut all types of metals, from mild steel to stainless steel as well as non-ferrous metals. But some highly reflective metals, such as aluminum and copper, are more difficult to cut. The maximum thickness of the metal that the laser can cut is determined by the laser source. In theory, the greater the laser power, the greater the thickness that can be cut. In addition, the professional knowledge of the machine operator will also affect the thickness of the laser cutting.

Fiber laser cutting machines are widely used in the manufacturing of advertising signs, kitchenware, sheet metal processing, metal parts, chassis and rack processing, cabinet processing, metal crafts, elevator panel cutting, hardware, auto parts, and electronic parts, nameplates, et

c

At baokun, we regard every request from our customers as first priority. Our team is always ready to give technical support for any customer at any time. All of our machines boast a warranty period of 3 years and lifetime of free technical consultation.

QINGDAO PRECISION LASER TECHNOLGY CO.,LTD produced a series of fiber laser cutting machine with high electro-optic conversion efficiency, A number of technologies, especially metal fiber laser cutting technology in terms of cutting thickness and cutting speed are advanced in China.